Manufacturing

the Future

State of the art sheet metal fabrication and machining processes across six facilities.

450,000 SF Manufacturing

State of the art metal fabrication processes across six facilities.

manufacturing since 1958

Traditional manufacturing processes combined with modern technology.

certified quality

Exceeding customer expectations through quality manufacturing solutions.

Unsurpassed customer satisfaction, rapid response, competitive prices & continuous improvement.

CNC PROCESSES DELIVER ADVANTAGES

-

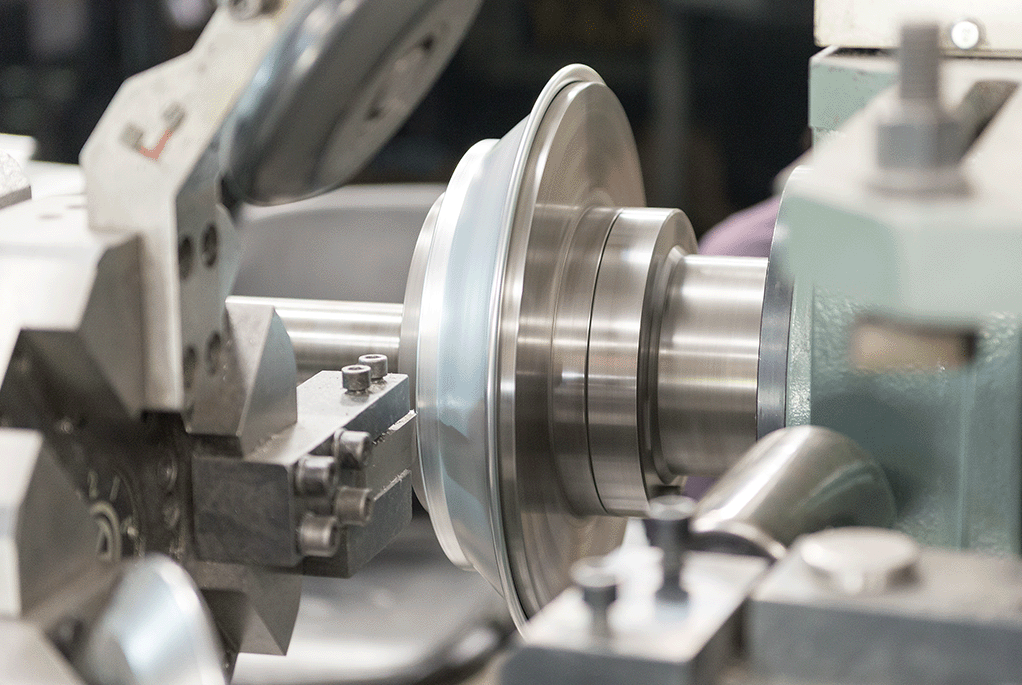

CNC Turning

Our capacity and experience are unmatched, with an innovative combination of CNC Turning and Milling. Combined with cellular manufacturing, we build high quality parts with competitive pricing.

-

CNC Milling

Manufacturing close tolerance CNC machined components with an innovative combination of CNC Turning and CNC Milling enables us to offer competitive costs for high-quality parts.

-

CNC Grinding

Expertise in all types of grinding that customers have come to expect, including Infeed, Endfeed, Thrufeed, Cylindrical, Internal and Blanchard grinding.

Vertically integrated processes

-

Broaching

Multiple broaching machines add speed and efficiency to manufacturing process. Vertical integration of all manufacturing departments offers unique and cost effective solutions for OEMs.

-

Welding

Full Robotic, Manual Mig and Tig, and Spotwelding production capabilities. Added value opportunities through custom designed fixtures often lower costs and shorten lead times.

-

Automatic Screw Machines

A highly efficient process designed to rapidly remove material while holding tight tolerances. This enables secondary operations while staying competitively priced.

-

Sheet Metal Fabrication

Multiple facilities and a large arsenal of fabrication equipment can deliver a high volume of sheet metal components and assemblies. Quality, efficiency, and material utilization are top priorities.

-

Powder Coating

Three in-house powder coating shops ingrained into our facilities are equipped to provide quality-tested pretreatment processes and state-of-the-art metal finishing. Precision and durability are guaranteed.

-

Metal Spinning

We offer an extensive library of standard tooling and custom tooling capabilities. Metal spinning is a cost effective way to improve manufacturability of axially symmetrical parts for extreme precision.

Join the Team.

Develop the Skills for Your Future.

“with J&E companies, I have a career in manufacturing. it’s more than a job.”

Learn new skills and gain opportunities to advance in your career. Join a team of skilled operators, machinists and technicians who use the latest technology and equipment to deliver exceptional quality metal components and assemblies.

Quality & Assurance, Engineering, Logistics & Assembly

Close-up of a metal grinding process with sparks flying around.

A laser cutting machine engraving patterns on a metal sheet.

A man operating a large industrial machine in a workshop.

A forklift in a warehouse with large metal containers stacked on pallets.

Honoring the Past. Ready for the Future.

J&E Companies’ foundation of quality, safety and metal versatility has been upheld for more than 60 years by the J&E and R&B divisions. Our six manufacturing locations totaling over 450,000 sq. ft. offer a single-service solution for high quality metal components and assemblies at scale.

We remain laser focused on being reliable, dependable and exceeding the expectations of our customers.